Rubber vulcanization for improved quality and durability of parts

Rubber vulcanization as a specialized process

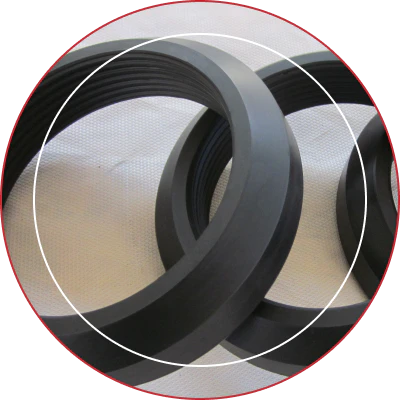

Rubber vulcanization involves bonding the rubber part to a substrate (metal, plastic, wood, etc.). It is a complex process with specific requirements, demanding precise procedures, technological equipment, and experience.

It’s crucial to correctly determine the start of vulcanization, which is marked by changes in the plastic-elastic properties of the rubber compound. This is followed by a state of under-vulcanization, where the compound has low elasticity, high elongation, and low tensile strength.

Rubber vulcanization concludes when the compound achieves optimal physical and mechanical properties. It is essential to accurately control the vulcanization process; otherwise, the compound can become sticky and soft, or excessively harden (especially in the case of synthetic rubbers).

Rubber vulcanization and its significance in industry

Rubber vulcanization plays a crucial role in various industrial sectors. This process enhances the durability of rubber products, making them more resistant to wear, chemicals, and extreme temperatures. In the automotive industry, rubber vulcanization is essential for manufacturing tires, seals, and other components that must withstand harsh conditions. In construction and engineering, rubber-coated metal parts are used to reduce noise, vibrations, and improve the longevity of machines and equipment.

Advanced rubber vulcanization techniques

Rubber vulcanization involves the use of advanced techniques and various chemical additives that accelerate the process and enhance the final properties of the products. The use of organic accelerators, such as sulfenamides, allows for a reduction in vulcanization time and an improvement in the mechanical properties of the rubber. These additives not only speed up the process but also increase the rubber’s resistance to aging, ensuring longer lifespans for mechanisms, machines, and equipment that include rubber-coated components (rubber-coated wheels, rollers, metal parts, and more).

Rubber vulcanization and its impact on product quality

Properly conducted rubber vulcanization is crucial for achieving high quality, durability, longevity, and reliability of the final products. Inadequately vulcanized rubber can lead to issues such as cracking, loss of elasticity, and reduced resistance to chemicals and heat. Therefore, it is essential that the vulcanization process is supervised by experienced professionals and follows the latest technological procedures.

Rubber vulcanization requires the correct pressure and temperature

It can be said that rubber vulcanization was discovered in 1839, when it was found that rubber, when exposed to increased temperature, does not remain plastic but becomes stronger and more elastic.

Following the discovery of vulcanization, rubber began to be widely used in almost all industrial sectors.

Over time, the vulcanization of rubber has been shortened from several hours to just a few minutes, thanks to organic compounds like accelerators, which not only speed up the entire process but also contribute to improving the aging resistance of the rubber compound. It’s important to emphasize that rubber vulcanization requires the correct temperature (approximately 140–180 °C, and up to 200 °C for synthetic rubbers), as well as the correct pressure, which improves the mechanical and physical properties of the rubber.

Rubber vulcanization under the supervision of experienced professionals

Rubber vulcanization, in addition to the use of accelerators, also requires another component—plasticizers to improve the processability of the compound. These plasticizers enhance tackiness and plasticity, but most importantly, they increase elasticity and durability while also affecting permeability to some extent. Rubber vulcanization is, therefore, a specialized process that should be carried out under the supervision of experienced professionals. Only then will the rubber-coated parts be properly treated, maintaining their functionality, durability, and longer lifespan depending on the environment in which they will be used.

Rubber vulcanization and its future

Rubber vulcanization is a rapidly evolving field that continually introduces new innovations and technologies. Research and development in this area focus on improving the properties of rubber, reducing production time, and minimizing environmental impact. Advanced technologies enable the creation of rubber products with even better properties and a wider range of applications.

In the coming years, rubber vulcanization will continue to be a key process that ensures high quality and long-lasting performance of metal parts and rubber products. LUSIK TRADE, s.r.o. is your reliable partner in this area. We are ready to provide you with the best services and expert advice.

At Lusik Trade, we are experts in rubber coating and have many years of experience in the production of rubber parts (rubber-coated wheels, rollers, etc.), which are used in virtually every industrial sector or as part of the production of other products.